If you are a direct mail marketer and haven’t worked with our structural design team yet, then you may be missing out. Recently I had the chance to sit down with Bill Anderson, an eleven-year veteran of SG360° and head of our Structural Design department, to talk about the importance of format design and what sets his team apart.

Q. How did you get started in structural design?

Q. How did you get started in structural design?

Bill: A happy accident as I like to put it. I studied fine arts and design in college, and didn’t really have print experience. Coming out of college I took a “temporary” job in printing with the intent of moving on to a career at a large ad agency where I’d design cutting edge ads in Wired or Rolling Stone. That stepping stone turned into a career in one of the most unique design fields. This path happened to be very common with most of the designers I’ve worked with in the industry. It’s a creativity one doesn’t really look for.

Q. What is the role of the Structural Design team?

Bill: Format evaluation and ideation. Our goal is to help our customers create formats that not only achieve their objectives and can be efficiently produced, but also give them new concepts to use.

From the evaluation standpoint, we’ll take a customer’s existing format and review it for production and postage efficiencies, making suggestions when needed. These suggestions could range from adjusting the format size slightly to run more impressions around or across the press, resulting in less waste and shorter production time, to changing the closing mechanism of a self-mailer from a wafer seal to a glue strip, eliminating a step in the production process while creating a more aesthetically pleasing look. Finding these opportunities up front during the design process can lead to significant time and cost savings on the back end.

We also confirm that a format design follows USPS postal regulations. Understanding these regulations is the backbone to creating direct mail. Not adhering to them can mean unnecessary postage expenses, and at worst, your mail doesn’t get delivered. Its no longer place a stamp and mail. Because the regulation intricacies aren’t black and white, we serve as the experts for our customers. We’re certified in mail piece design through the USPS and work closely with our Director of Postal Affairs to understand the impact of new rules as they come out. Using this knowledge, we’ll suggest slight tweaks or, in some cases, dramatic design changes that can save thousands in postage costs.

In addition to reviewing existing designs, we also help customers bring new concepts to life. Often they’ll have an idea of what they want but aren’t sure exactly what that looks like or how to make it happen. We help them do that. For example, we recently had a customer ask for a booklet with a coupon. Our goal here is to provide a range of possibilities and unique formats that expand on their initial concept to find an ideal format that will achieve their objectives. In this instance, we created four physical concepts in varying sizes and features. Some ideas may be out of the box, but may spark interest in a modified version of the initial request.

Q. Why is format design so important?

Bill: Designing a direct mail piece is about more than just the creative design, getting the format right is critical. The messaging of the piece is what ultimately sells the product, but it’s the format that drives the initial engagement. And getting that format efficiently produced is what’s crucial to its overall performance. Say you create a gorgeous kit with an integrated video screen and personalized booklet. When you’re mailing that kit to 50,000, 100,000, even 200,000 people, the costs can quickly escalate and if your piece isn’t designed for the most efficient production and mailing, your ROI goes right out the door.

Here’s another, probably more common example. You have a self-mailer that measures seven by ten and a half inches. At this size you’re looking at paying the USPS flat-rate which means you’re paying $.65 a piece. If you adjust the format size down by just one inch to six inches by ten and a half, you’re now sitting at the USPS letter-size rate which is just $.29 per piece. That $.36 per piece difference quickly starts to add up.

Q. What sets your team apart from other format design teams?

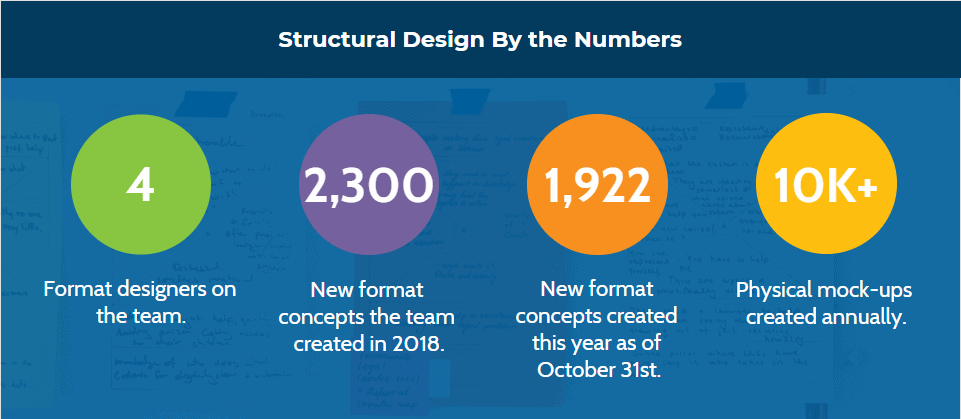

Bill: Really from what I’ve seen, we have two key advantages: the expansiveness of our production capabilities and our location. Because our production platform spans web inline, sheetfed and digital printing we’re involved in both web finishing and lettershop finishing. Having all of these production options and the experience in them, has enabled us to really design to any type of finished product, whereas for other printers who may only have web finishing or lettershop finishing, their format designers are limited to a single production method. We have the experience and ability to design hybrid packages that are produced and finished without going to an outside resource.

Our second advantage is being located onsite with our manufacturing. Because we sit where the programs are produced, we collaborate with our production teams in real-time. At my previous organization, I was located miles away from our nearest production facility and a state away from the others. There was a lot of time lost reaching out to the plant. If changes were needed by manufacturing, it was difficult to get an immediate response and then to follow up on the changes. By being right here, we’re able to walk down the hall, talk through the formats and make any needed changes, all in a few minutes. Not to mention being able to physically see how the equipment works and how a program is going to run and make on the fly changes when needed.

Another benefit of being on site is our ability to produce sample cut downs. Because we’re here, we can grab proofing sheets right off the press and use our high-speed CAD cutter to cut down and give to the customer immediately versus adding time by having to send to an outside vendor. This CAD system also helps my team create customer mock-ups in half the time normal hand cut mock-ups take. These pieces are instrumental in sharing new ideas with clients.

Q. What is the toughest part of a format designer’s role?

Bill: When it comes to format design, there are three elements we need to be mindful of – the quantity, the complexity, and the turn-around time. These elements identify how a piece should be produced and how it’s going to be finished – inline on the press or offline in the lettershop. Determining the construction through the finishing method is the toughest part of our role.

While it’s important to know what type of printing process will be used, understanding the final finishing is critical in determining which press the piece will actually go on. That’s where our function comes in. We handle the complex engineering of the piece – the folding, die-cutting, placement of affixed cards, glue closures, etc. All these elements are handled during the finishing process, making it a necessity for us to know the ins and outs of how our equipment works. If we are looking at a web finished project, we need to build to our large assortment of inline presses. We have four inline presses unique to the entire industry, each having various capabilities and advantages. On the other hand, if the the piece is to be sheetfed or digitally produced the finishing will be handled in a lettershop with automated equipment or even handwork, requiring different format considerations.

Q. What are some of the format trends you’re seeing?

Bill: It depends on the market. In the automotive arena, we see a strong demand growing for four color variable information. Retail is still strong in offer cards that consumers can pocket and take in store or use when ordering online. Showcasing as much product information in a letter rate booklet is also very common.

In terms of the financial area, there is a lot of testing involved. Before going into full scale production, they want to see what their response rates are going to look like and identify any changes that need to be made – to the creative or the format before ramping up. With these requests our team will identify formats that can be both web finished and lettershop finished, working within the parameters of both sets of capabilities. We can test the product by running in our lettershop a piece that will mimic a full run in an inline facility.

Q. What advice do you have for marketers and creatives when designing their direct mail format?

Bill: I would recommend them considering how much content they have on a piece. If there is minimal copy or content, take advantage of the piece with a unique feature. A pop up or large die cut call out. Something that will intrigue the recipient to take action.

If there isn’t a lot of information and just an offer, postcards are always quick mail devices. However, they have a tendency to get lost in the mail due to their simplicity. Adding a couple of panels may cost a little more in paper, but the “mail moment” created by opening the device can help drive the campaign further.

On the other end, if you have a lot of variable information that needs a level of security that a folded self mailer may not offer and a standard conventional envelope isn’t attractive enough, take advantage of web produced envelopes with enclosed components. Add high color and coatings with matching variable information. Die cut features or unique pockets can add interaction and make the piece standout from the everyday envelope solicitation received and often discarded.

Are you looking for help identifying your next direct mail program format or want to have your current package evaluated for production and postal efficiencies? Bill and the rest of the Structural Design team are here to help. Simply contact us today to get started.